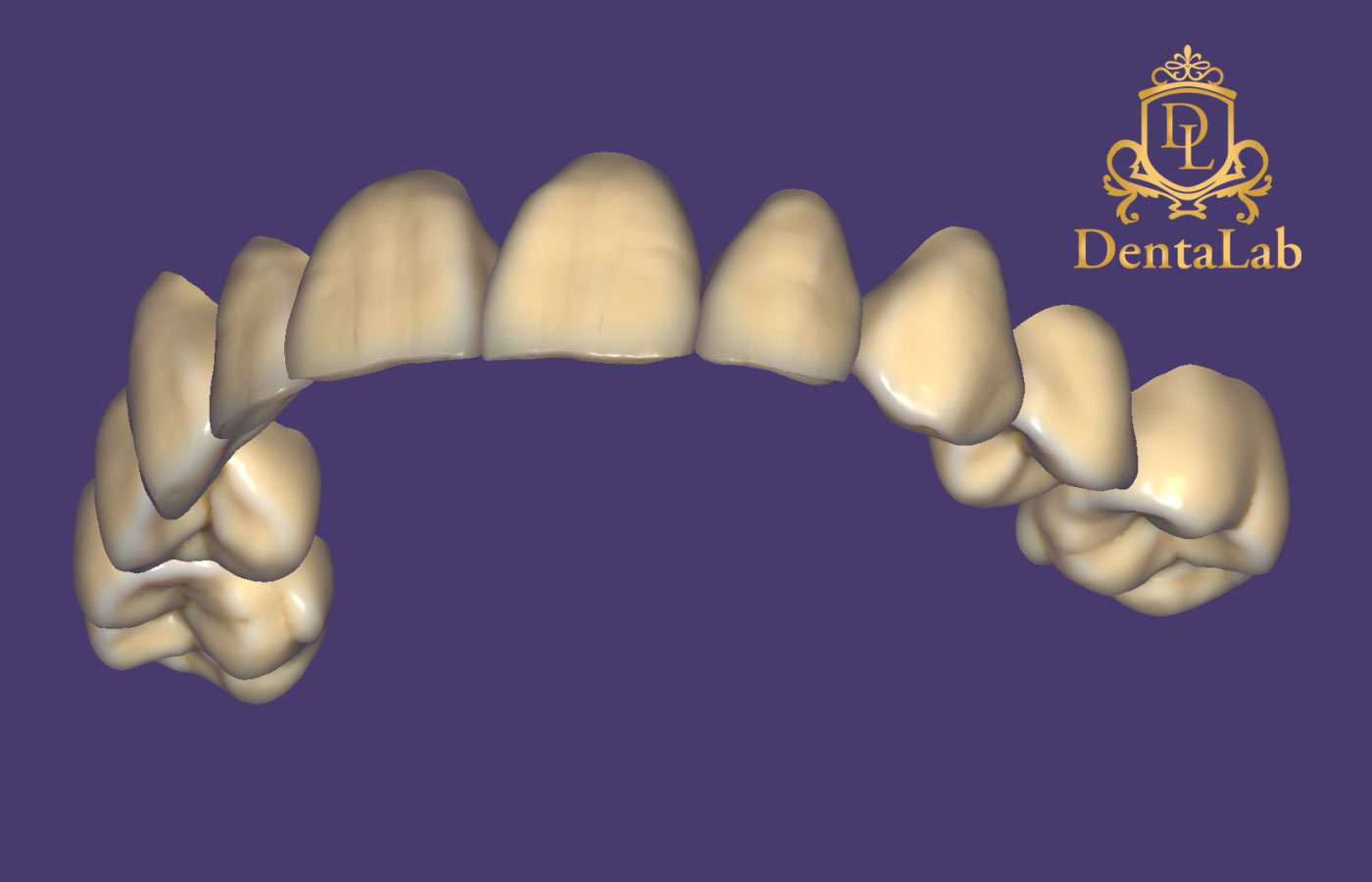

Milling Center & 3D Printing

CAD/CAM stands for Compute Aided Design/Computer Aided Manufacturing.

DentaLab CAD/CAM team has more than eight years of experience in this field. The most modern software and hardware is used.

We use the most modern soft- and hardware:

Stone models and silicone impressions are scanned using Medit Identica Hybrid scanner

The work is designed with exocad software

The products are manufactured using VHF Impression S5, S2, K5, N4 milling machines and Stratasys Objet30 Orthodesk, Stratasys Eden 260V, Stratasys Eden260VS 3D printers

DentaLab CAD/CAM department offers scanning, designing, milling and 3D printing service.

Millable materials

Nacera zirconium (pre-shaded transparent Pearl, multilayer transparent Multi-Shade)

Alien zirconium ( Alien high translucency, Alien multi-layer, Stardust multi-strength, Extreme translucency

Priti zirconium (Opaque)

Takana zirconium Enamel Multi-5 (5 layers of pre-mixed shades and translucency)

Polident PMMA (monolayer, multilayer, splint)

MIT Abutment pre-mill abutment (Design and mill our pre-mill abutment as you need)

Scheftner Dental CoCr & titanium

JUVORA PEEK-OPTIMA

DESS-Abutments pre-mill abutment (Design and mill our pre-mill abutment as you need)

3D printable materials

MED610 (Bio-compatible transparent PolyJet photopolymer for intraoral devices requiring prolonged skin contact of more than 30 days and short-term mucosal-membrane contact of up to 24 hours)

MED690 (A dark beige material for printing models)

Rigid Opaque: WeroWhitePlus, VeroBlackPlus, VeroGray, VeroBlue

Rubber-like: TangoPlus, TangoBlackPlus, TangoBlack, TangoGray

Transparent: VeroClear PMMA ja RGD720